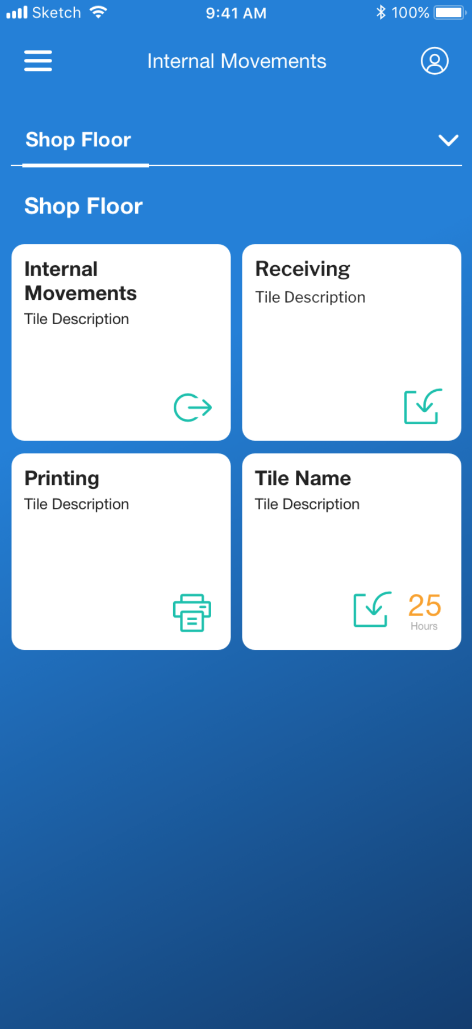

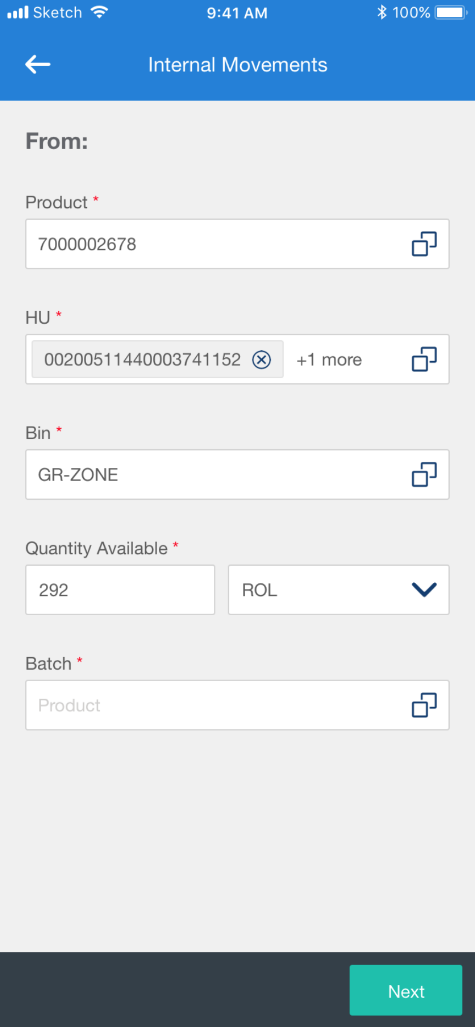

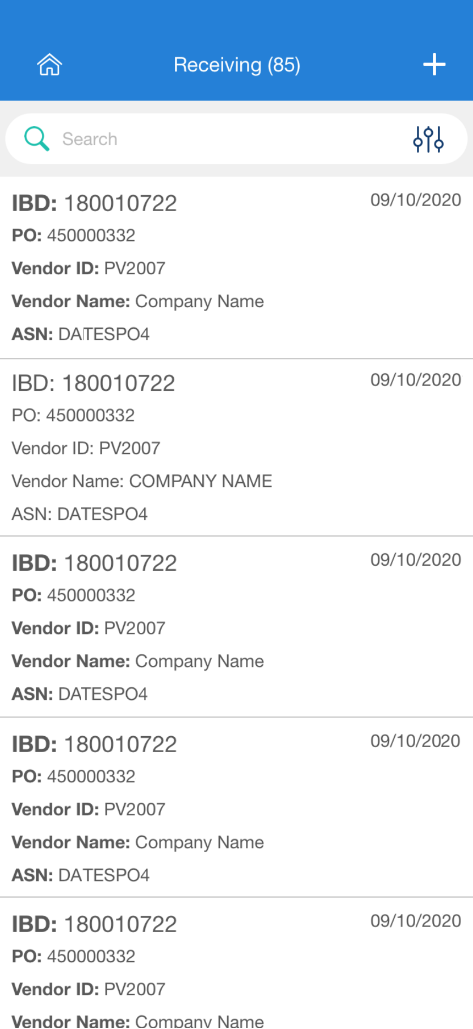

To process manufacturing-related data, the client had to manually maneuver through multiple screens and systems. This process was time-consuming, resource-intensive, and prone to human error. Mindset was approached to find a simpler, more streamlined solution that would reduce errors and training costs. After conducting Design Thinking workshops with all stakeholders, the team mapped different situations, created user personas to understand process requirements, and developed high-resolution prototypes. The final solution better integrated the legacy ECC and EWM systems, bringing together all relevant data into one consolidated system that reduced time requirements and increased efficiency.

The client was able to reduce complex ECC workflow into a streamlined EWM-driven process accessible on mobile devices.

Related content

A Beginner’s Guide to Procurement

There are many ways to improve business performance, and one of them is by practicing Value Supply Management. Buying is…

Press Release: Announcing the winners of the 2023 EXperts Awards

Announcing the winners of the 2023 EXperts Awards CNHI, Ecolab, Entegris, and Xcel Energy are recognized for Solutions that advance…

The Value of Continuous Delivery: Test-Driven Development

SAP is changing many aspects of how customers consume and act on business information. In the past, we have often…