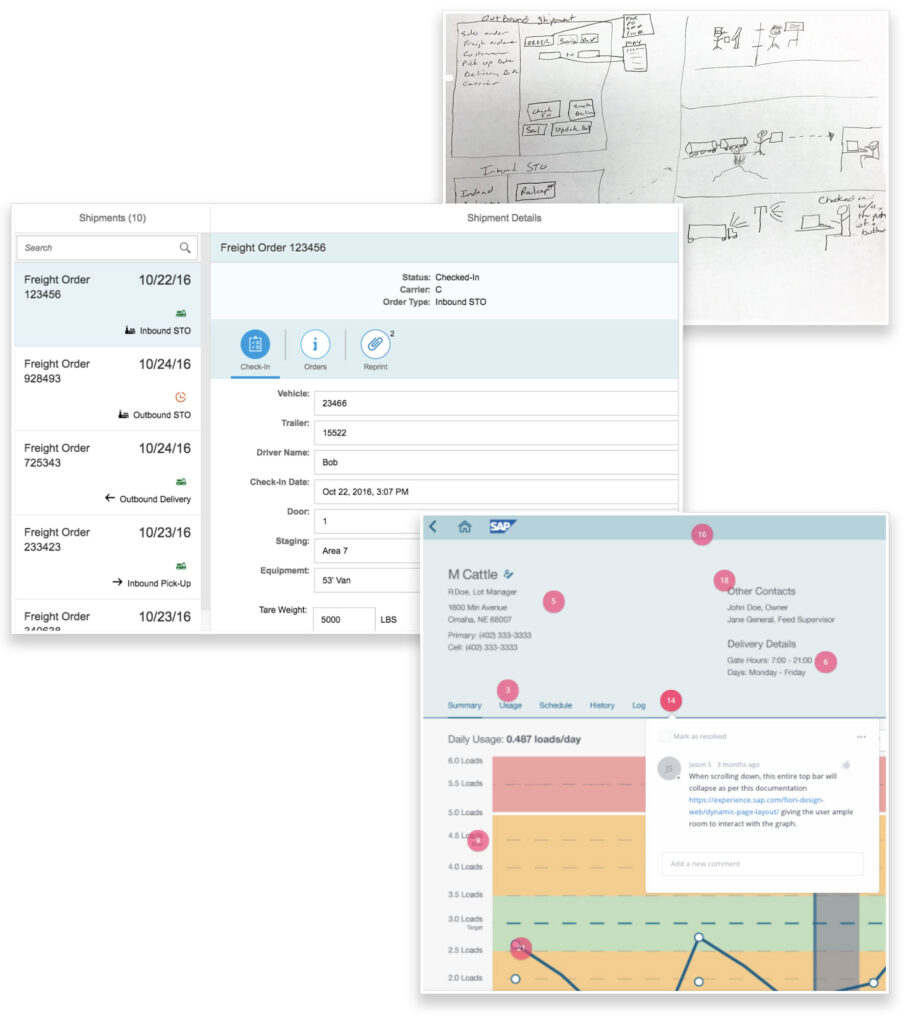

Shipment and warehouse activity tracking was problematic for the client. Trucks experienced inordinate waits in line at the warehouse waiting to be checked in, real-time updates were impossible, and shipments were difficult to track and deliver on time. This led to excess costs, challenging resource scheduling, and workflow impairment.

The client engaged Mindset to design and implement a better system for real-time tracking and reporting of shipments and plant activity. Mindset experts utilized a Design Thinking approach and created a standalone prototype of the application that showed them engagement at every stage.

Using Agile methodology, the Mindset team then created a high-resolution prototype that addressed their issues in just 7 days, and met the project timeline using Fiori. The new system allowed the client to reduce costs by $250,000, implement changes without disturbing the core of the business, and quickly capture business value.

Using Fiori, the team was able to go from whiteboard ideation to high-resolution working prototype in just seven days.

Related content

Addressing new Real Estate Standards with the SAP ERP Flexible Real Estate sub-Module

In December of 2018, new lease accounting standards for real estate were put into effect by the Financial Accounting Standards…

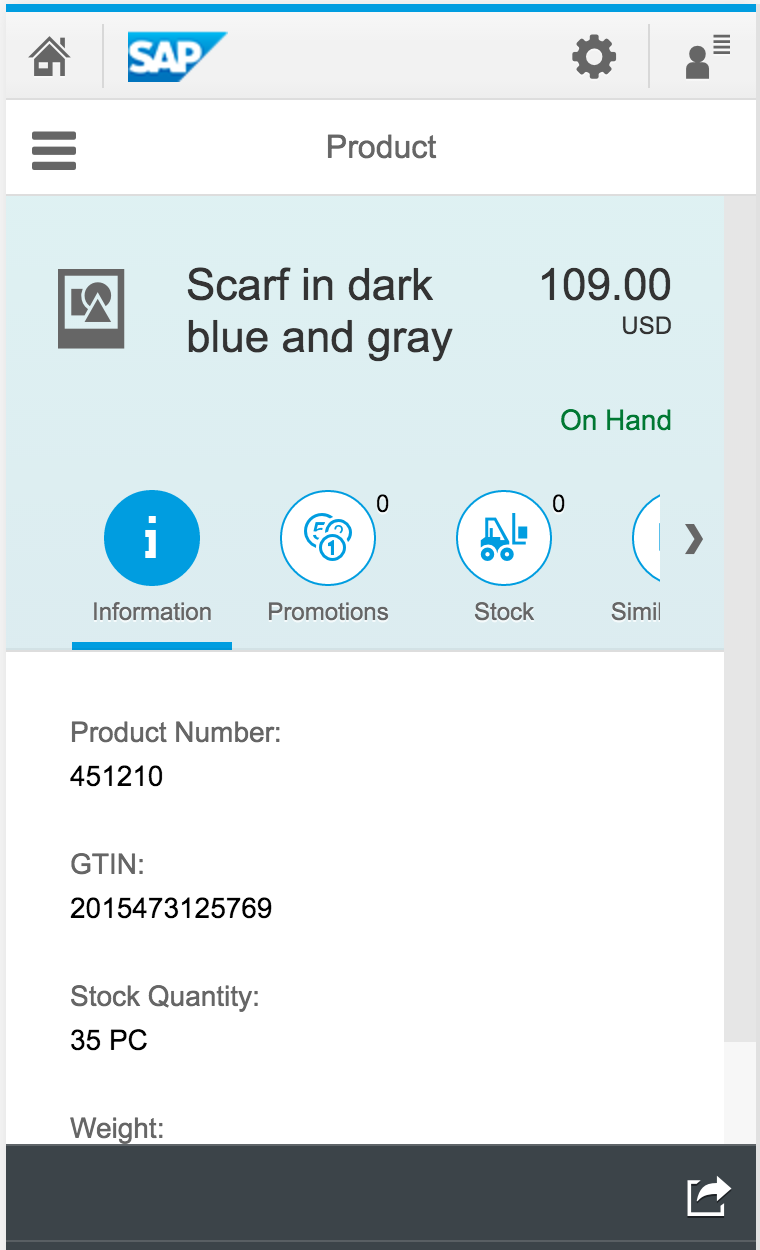

Fiori Tab Strip

This Tab Strip seems to make its way into most standard SAP Fiori apps, such as the Retail Product Look…

Welcome Michael Allen!

Mindset is extremely excited to welcome Michael Allen to the team as a Senior Account Executive focusing on the Mindset’s…