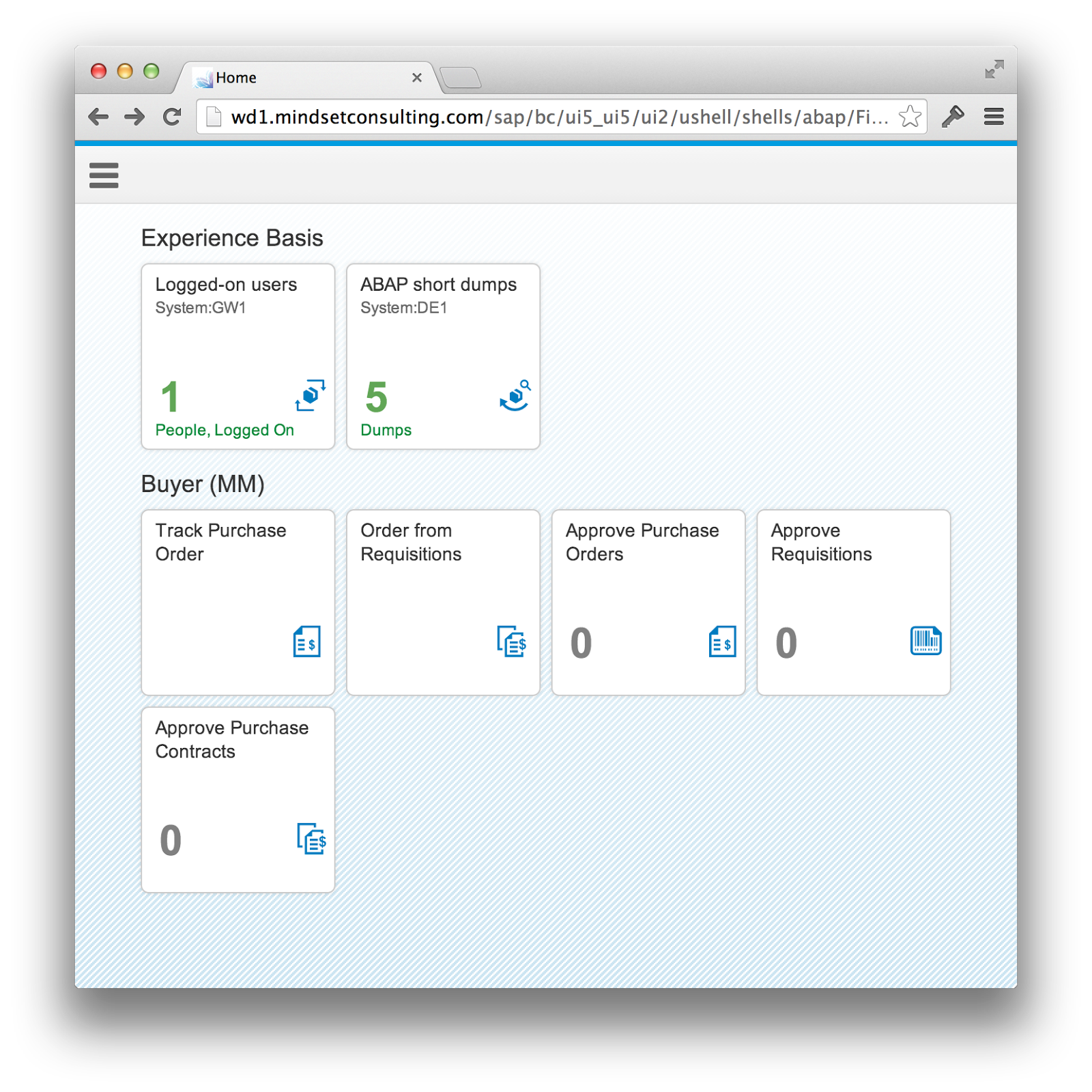

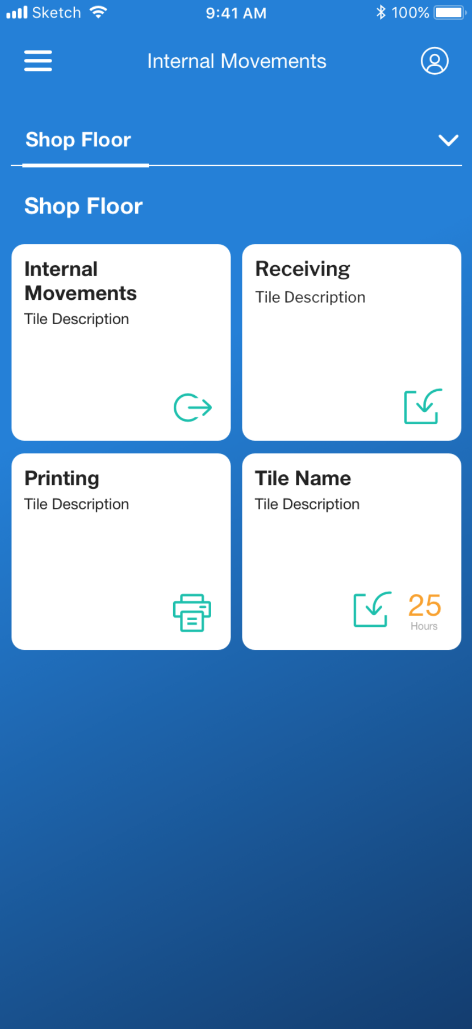

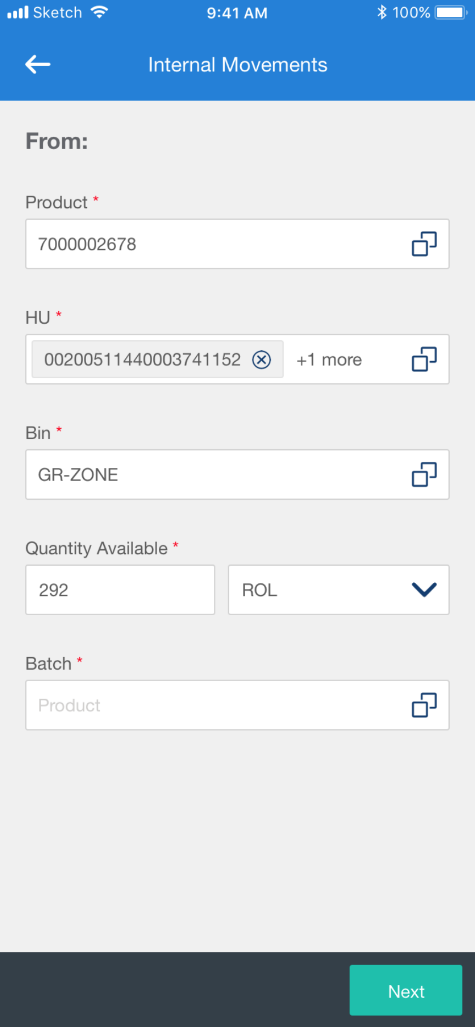

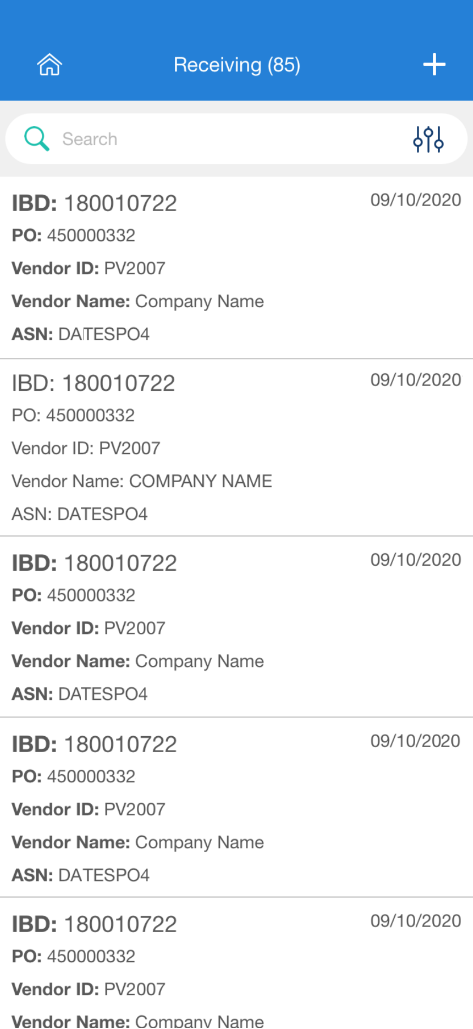

To process manufacturing-related data, the client had to manually maneuver through multiple screens and systems. This process was time-consuming, resource-intensive, and prone to human error. Mindset was approached to find a simpler, more streamlined solution that would reduce errors and training costs. After conducting Design Thinking workshops with all stakeholders, the team mapped different situations, created user personas to understand process requirements, and developed high-resolution prototypes. The final solution better integrated the legacy ECC and EWM systems, bringing together all relevant data into one consolidated system that reduced time requirements and increased efficiency.

The client was able to reduce complex ECC workflow into a streamlined EWM-driven process accessible on mobile devices.

Related content

How To Setup the SAP Fiori Launchpad

This blog is consistently one of the most read Fiori blogs on the internet. Unfortunately it’s a bit out of…

Mixed Up About MXDP?

SAP just announced that it has been recognized (for the second year in a row) as a Leader in Gartner’s…

2020: the Year our Customers and Prospects became my Friends

2020 has already been the year of many firsts. In many ways the changes have been so big, it’s hard…