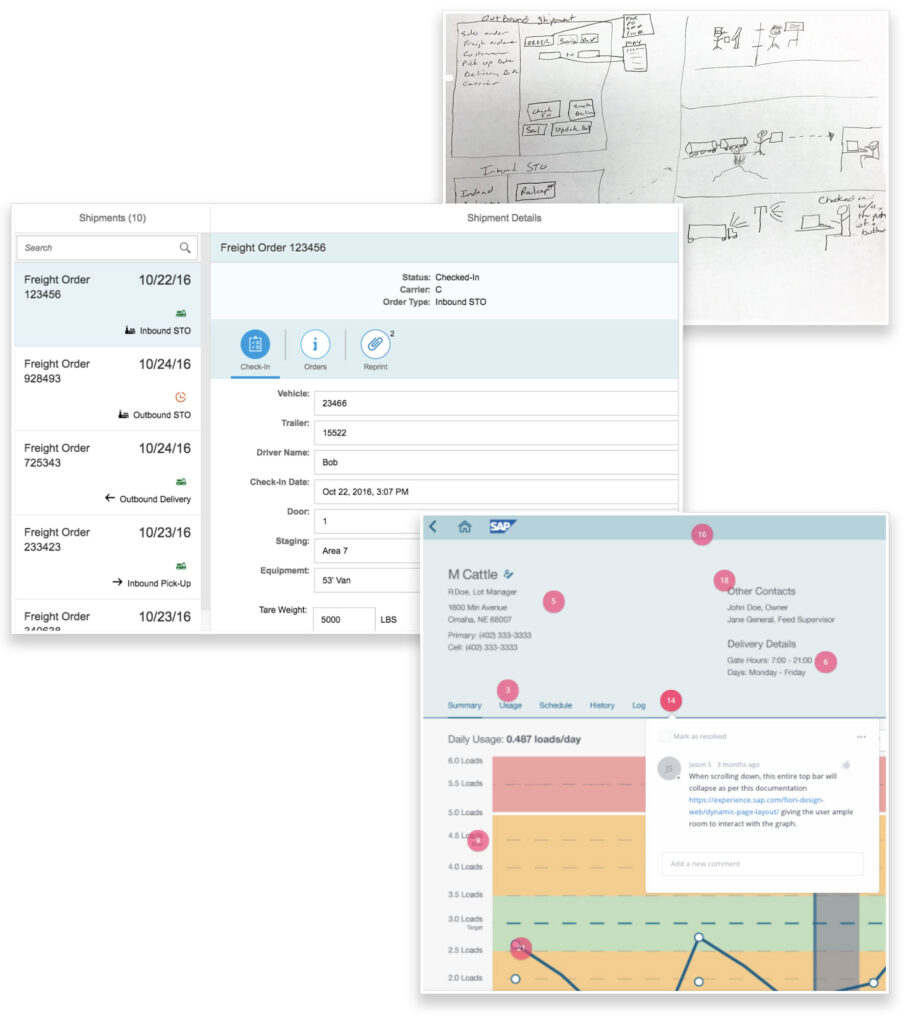

Shipment and warehouse activity tracking was problematic for the client. Trucks experienced inordinate waits in line at the warehouse waiting to be checked in, real-time updates were impossible, and shipments were difficult to track and deliver on time. This led to excess costs, challenging resource scheduling, and workflow impairment.

The client engaged Mindset to design and implement a better system for real-time tracking and reporting of shipments and plant activity. Mindset experts utilized a Design Thinking approach and created a standalone prototype of the application that showed them engagement at every stage.

Using Agile methodology, the Mindset team then created a high-resolution prototype that addressed their issues in just 7 days, and met the project timeline using Fiori. The new system allowed the client to reduce costs by $250,000, implement changes without disturbing the core of the business, and quickly capture business value.

Using Fiori, the team was able to go from whiteboard ideation to high-resolution working prototype in just seven days.

Related content

Resume Tips for Technical Professionals

Over my 5 years of working in the recruiting environment, I have seen almost every type of resume imaginable; different…

Mindset Food & Supply Drive

Minneapolis and the Twin Cities as a whole is hurting right now. Sarah Lewis from Mindset is organizing a Mindset…

Innovations in BTP – The SAP Launchpad Service part 2: Setting up your Launchpad Site

In my previous blog, I introduced you to the SAP Launchpad service, a repository of innovative solutions and applications for…